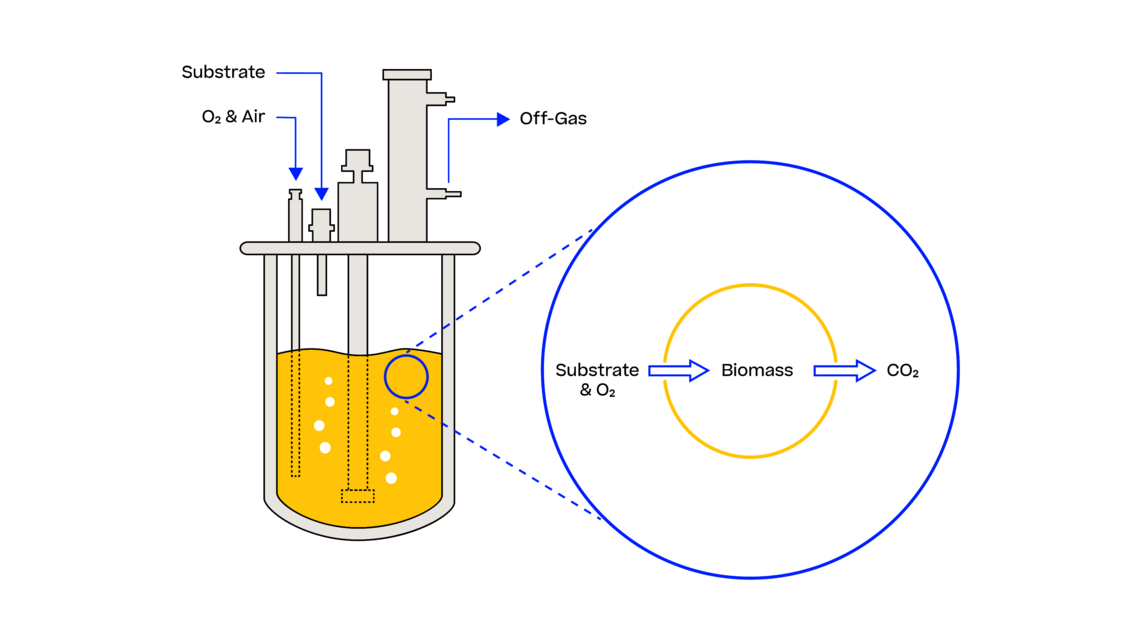

Biomass soft sensors utilize existing measurements from hard sensors and mechanistic or hybrid relationships to predict biomass levels in real-time. These software-based sensors rely on continuous data streams from various sensors deployed throughout the bioprocess, including measurements of incoming and outgoing gases like O2 and CO2, and the amount of substrate entering the reactor. The soft sensor integrates these data points through mathematical equations to provide accurate biomass estimates, eliminating the need for manual sampling.

- Data requirements: Continuous data streams from hard sensors are essential.

- Process knowledge: Understanding the specific organism and its product formation.

- Analytics infrastructure: Robust infrastructure like PAS-X Savvy to automatically import and analyze data.

- Calibration and validation: Iterative calibration and validation to ensure accuracy.

The benefits and applications of biomass soft sensors

The application of biomass soft sensors spans a wide range of fermentation processes, including microbial production systems such as bacteria, yeast, and filamentous fungi, as well as mammalian cell cultures like CHO cells. These sensors can monitor and optimize the production of various primary and secondary metabolites, including recombinant proteins, antibodies, and enzymes.

Key benefits:

- Enhanced process monitoring & control: Real-time monitoring of cell growth allows for optimized harvest times and increased productivity.

- Improved process optimization: Insights into biomass concentrations help refine process parameters.

- Quality control: Large data offsets can indicate potential inaccuracies, ensuring better adherence to GMP standards.

- Cost reduction: Minimizing manual measurement procedures reduces operational costs.

- Reduced contamination risks: Continuous monitoring without physical sampling lowers contamination risks.

PAS-X Savvy: Deployment & results

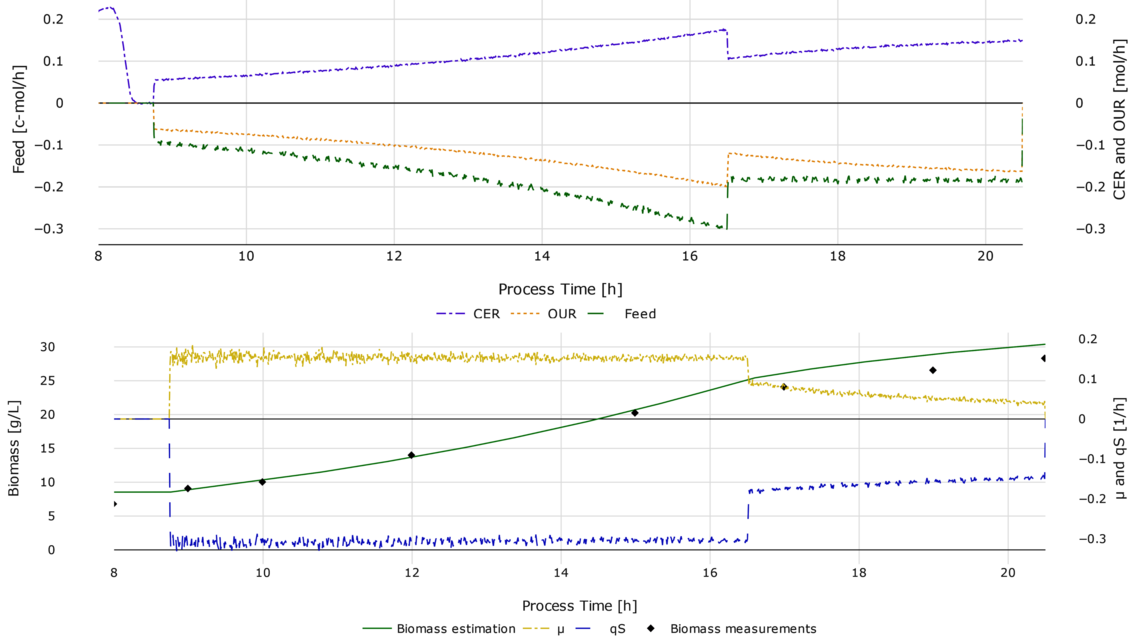

Once calibrated, the biomass soft sensor can be deployed within seconds. The user can easily adjust key parameters through a straightforward configuration process, providing the flexibility to apply the calculation to various fermentation processes. In addition to measuring biomass concentration, the soft sensor also provides real-time performance metrics such as the specific growth rate (µ), substrate uptake rate (qS), oxygen uptake rate (OUR), and carbon evolution rate (CER). These results can then be directly visualized to gain insights into the bioprocess state, enabling real-time process control and post-production analysis (see Figure 2 and 3).