Solutions

Software solutions

Handling systems

Inspection

Packaging machines

Packaging solutions

Consulting

Services

Ticket System for Machine Services

Expert knowledge at one click

You can benefit from our many years of experience and our profound expertise. We’ve put together a selection of informative brochures, comprehensive white papers, and much more about the products, solutions, and services.

The Körber Ecosystem

Learn more how to benefit from Körbers holistic solutions in pharma

Download PDF

Flyer

Your Digital Maturity: Assessment and Strategy

We guide you in your digital transformation in any phase: From the evaluation of your current digital maturity level with precise industry benchmarking to exploring quick wins with huge ROI potential. And of course, we support you with ongoing strategic consultancy to implement appropriate Pharma 4.0 components.

Tailormade Solutions

Get to know our services and your advantages for a Business Process Management Concept.

Enterprise Manufacturing Intelligence

Transform your data into valuable knowledge by using Enterprise Manufacturing Intelligence

Harmonize machine data up to all IT levels

Learn how Line Optimizer-Execute can get you 30% higher machine availability.

Have better control over your supply chain

Integrated serialization solutions Level 1 to level 5.

Track & Trace solution for Asia Pacific

Get to know our track and trace solutions for Asia Pacific

Agile machine qualification

Our innovative agile machine qualification methodology uses our unique Körber ecosystem synergies to accelerate your time-to-market.

Brochure

Visual Inspection Qualification Services

Training, qualification, and validation services by experts.

Case Study

Business process management Case Study

Business process management at Top-10-global-pharma-companies

Case Study: Line Optimizer

Learn how Novo Nordisk uses Line Optimizer to support an efficient biotech production

Luye Pharma Case Study: Efficient global serialization

The Luye Pharma Case Study: How Luye Pharma solved serialization with Körber in no time.

Occlutech Case Study: Medical devices experts join forces for on time MDSAP* readiness

The Occlutech Case Study: From requirement analysis to project implementation - we are your personal partner and your pharma technology expert

Develco Case Study: Managing compliant processes on time

The Develco Case Study: Benefit from agile pharma project management combined with methodical execution according to GAMP®5

Whitepaper

Get your machine to production as quickly as possible

Machine Qualification Services for the Switch 75

Newsletter

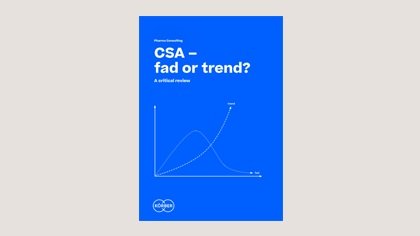

Computerized System Validation or Assurance

Read in less than 10 minutes why CSA is not a replacement for CSV!

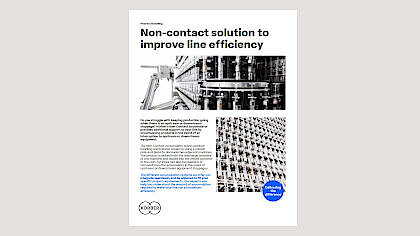

Factsheet: Non-Contact Accumulator

Körber can provide a complete non-contact system to protect your pharmaceutical products and promote enhanced line OEE.

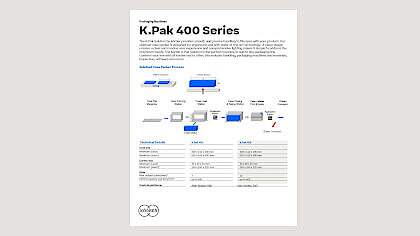

Datasheet: K.Pak 400 Series

Simple and Clean: Sideload Case Packers Built for the Pharmaceutical Industry

Körber Accumulation Solutions

Reduce downtime and optimize your line’s efficiency with our accumulation solutions

Syringe Transport Systems

Learn how to eliminate glass-to-glass contact with our smooth and seamless handling systems.

Factsheet: Vial Conveying

Learn to elevate product safety with effortless machine flexibility thanks to Körber new vial transport system

Flyer: Tray Handling Solutions

Discover how Körber can handle more of your products per tray than ever before

Brochure

Brochure: Inspection Technologies

Particles, cosmetic defects, container integrity: whatever the task, we have the perfect inspection solution for your product.

Brochure: DE.SY.RE

High-performance inspection combined with de- and re-nesters: the perfect inspection system for large scale production lines.

Brochure: Switch 75

Flexible inspection platform for small production batches - handles syringes and vials on the same machine

Brochure: Switch 350

Flexible high-performance inspection up to 350 containers per minute for syringes and vials – on one single machine

Brochure: Automatic inspection machines

Inspection, handling, control - a Körber inspection solution is more than the sum of its parts: A comprehensive overview of the features and benefits of our inspection machines.

Brochure: Semi-automatic inspection machines

Comprehensive overview of the features and benefits of our semi-automatic inspection machine V90+

Case Study

Case Study: Eject-X

Eliminate false ejects with deep learning and make your efficient camera inspection even more powerful.

Flyer

Flyer: Remote FAT for inspection machines

Remote Factory Acceptance Test: preparation, implementation, follow-up

Flyer: Pharma Academy Inspection

Classroom training, web-based training, blended learning, virtual classroom - find the best suitable training concept for you.

Flyer: Vision Adjustment Tool

The key to safe, fast, cost-effective validation of pharmaceutical inspection machines

Flyer: MVIC

Manual inspection: Our user friendly platform MVIC facilitates all manual inspection applications in the pharmaceutical market - in accordance with USP1790

Factsheet: Switch 75

Technical details of our flexible Switch 75 inspection machine (onepager)

Factsheet: Switch 350

Technical details of our flexible high-performance inspection machine for syringes and vials on one machine

Flyer: EVE LabUnit

Plug & inspect: Our mobile inspection unit for testing production parameters in laboratory environments, and suitable for countless other inspection and testing applications.

Whitepaper

Whitepaper: The principle of particle inspection

A simple and compact summary of the USP <1790> guideline, illustrating the individual test methods using Korber inspection machines as examples.

Whitepaper: Knapp Test Methodology

Comparing the inspection efficiency between manual inspection by human operators and machine inspection for particles in liquid products.

Whitepaper: Container Closure Integrity Testing (CCIT)

Overview of different CCIT methods currently applied in the pharmaceutical industry.

Best practice: Bubble-X

With Bubble-X, reliably distinguish glass particles and air bubbles in liquids - and thus avoid up to 50 % false rejects.

Training program

Brochure: PAS-X MES Training Program 2025

Out-of-the-box, high quality training program that ensures the success of your pharma, biotech, and cell and gene therapy projects.

Download PDF file (4 MB)

Articles & white papers

Brochure: PAS-X Integrator partner program

Take the next step to your company’s success as a PAS-X Integrator

Whitepaper: How C(D)MOs embark on pharma digital transformation

Contract development/manufacturing organizations in today's pharmaceutical markets are facing major challenges. Digitalization of key manufacturing and supply chain processes can help them to become more agile.

Whitepaper: Addressing Cell and Gene Therapy Manufacturing Challenges with Digital Solutions

The increasing demand for CGT requires scaling of production pipelines. Digital solutions are needed to support commercial production. In our whitepaper, we analyze the impact of Pharma 4.0 on CGT manufacturing and look at different options such as cloud-based and software-as-a-service offerings.

Interview: Evolving CGT with MES & cell orchestration

In this interview Judith Koliwer PhD (Körber) and Matthew Lakelin PhD (TrakCel) explain how Manufacturing Execution Systems (MES) like Werum PAS-X MES are driving the advancement of cell & gene therapy manufacturing.

Interview: New Werum PAS-X MES 3.3 Suite available

In our interview, Product Manager Oliver Busch talks about the release of our latest MES version: Werum PAS-X MES 3.3, the market-leading NextGen MES for pharma, biotech and cell & gene, driving cloud native and SaaS operations.

Whitepaper: The 5 principles of optimal MBR design

How digital recipe design secures the long-term success of an MES implementation in a pharma or biotech factory

Whitepaper: The 5 principles of optimal MBR design (Italian)

How digital recipe design secures the long-term success of an MES implementation in a pharma or biotech factory

Whitepaper: Why cell & gene C(D)MOs benefit from digitization

Learn how Electronic Batch Recording (EBR) enables the identification of the material at any point in time, thus facilitating ATMP compliance.

Download PDF

Whitepaper: Value Story PAS-X MES

Simplified documentation, accelerated workflows, and improved quality of products and processes with PAS-X MES

White Paper: AI in tomorrow's pharma and biotech industry

How to use artificial intelligence to uncover hidden business value in the regulated pharmaceutical and biotech industries.

White Paper: Return on investment - what is the cost of not doing MES?

Learn more about major saving areas with manufacturing execution systems (MES) and typical steps to evaluate ROI.

White Paper: How to speed up cell & gene therapy treatments

Reduce the number of manual operations and eliminate operator errors: Learn how a manufacturing execution system (MES) can address the unique production problems of cell & gene therapies.

White Paper: 5 benefits of using an MES for pharma and biotech

How to save time and effort and avoid risk in your pharma or biotech production.

White Paper: How to scale-up cell & gene therapy - digitization of supply chain

Learn how a manufacturing execution system (MES) addresss the unique biopharmaceutical supply chain challenges of cell & gene therapy logistics.

White Paper: How an MES supports your business continuity

Remote services and digital manufacturing keep your pharma & biotech operations running during crisis situations.

Article: ISPE Pharma 4.0™ SIG and its working groups

"By Christian Wölbeling and the ISPE Pharma 4.0™ Special Interest Group Working Group Leads The ISPE Pharma 4.0™ Special Interest Group (SIG) launched in 2015 to provide a road map for new challenges of digitalization, Industry 4.0, and the smart factory. The SIG addresses how pharmaceutical industry stakeholders, including regulatory authorities, can achieve benefits from Pharma 4.0™ initiatives. "

White Paper: How to ensure a holistic process characterization in biotech & pharma

Data management and analytics software substantially contributes to a successful process characterization.

Brochures

Brochure: PAS-X CMC Innovation Consulting

Our experts leverage best-in-class Data Science tools to optimize your entire process lifecycle, from process development to manufacturing.

Brochure: PAS-X Integrator partner program

Take the next step to your company’s success as a PAS-X Integrator

Brochure: Werum PAS-X K.ME-IN

PAS-X K.ME-IN offers you innovative biometric authentication solutions for pharma and biotech plants using fingerprint, iris scan, face recognition or a combination of those.

Brochure: Werum PAS-X MES

The Werum PAS-X MES manufacturing execution system helps you to digitize your pharma and biotech production.

Brochure: Werum PAS-X MES (Italian)

The Werum PAS-X MES manufacturing execution system helps you to digitize your pharma and biotech production.

Brochure: Werum PAS-X KPI

PAS-X KPI is a lean, standalone software product for live monitoring of your production and packaging lines to improve the shop floor performance of pharma and biotech facilities.

Brochure: Werum PAS-X KPI (Italian)

PAS-X KPI is a lean, standalone software product for live monitoring of your production and packaging lines to improve the shop floor performance of pharma and biotech facilities.

Brochure: Werum PAS-X Plug & Produce

PAS-X Plug & Produce allows you a fast and easy integration of machines and automation systems into a pharmaceutical or biotech production environment – a prerequisite for the implementation of many Industrie 4.0 solutions.

Brochure: PAS-X for Cell & Gene Therapy

Werum PAS-X MES digitizes your cell & gene therapy manufacturing, targeting key challenges for cell & gene therapy companies.

Brochure: Werum PAS-X Savvy

Werum PAS-X Savvy revolutionizes managing, analyzing and reporting of your pharma and biotech process data.

Brochure: Werum PAS-X Savvy (Italian)

Werum PAS-X Savvy revolutionizes managing, analyzing and reporting of your pharma and biotech process data.

Brochure: Werum PAS-X Packaging – integrated IT solution

Learn how we support you to optimize your packaging line and ensure right-first-time production.

Brochure: Up to 98% higher quality with PAS-X MES

Simplified documentation, accelerated workflows, and improved quality of products and processes with PAS-X MES.

Brochure: PAS-X MBR Services

Our range of best-in-class MBR services (MBR Help Desk, MBR Health Check, MBR Studio) increase efficiency, reduce costs and accelerate the success of your MES project

Factsheets

PAS-X Savvy Manufacturing Dashboards

Transform your PAS-X MES data into real-time manufacturing intelligence. Analyze equipment usage and exceptions, visualize batch review cycle times, streamline CPV and automate reporting – all with PAS-X Savvy.

PAS-X K.AI – AI-powered gateway to smarter PAS-X operations

Chat-based assistant delivering real-time answers to support efficient use of PAS-X MES products

Factsheet: Integrated process modelling with Werum PAS-X Savvy

With its breakthrough innovation Process Models (PMs), Werum PAS-X Savvy enables a holistic control strategy, deviation management and batch release in real time

Factsheet: Faster time to market through digitization of the complete product lifecycle

Werum PAS-X MES and Werum PAS-X Savvy enable automated data analysis in cell & gene therapy manufacturing. By leveraging an iterative approach of process digitalization, data analysis, process optimization and validation, CGT companies can drastically reduce time to market.

Factsheet: How to quickly achieve optimal profitability in precision fermentation with PAS-X Savvy

Achieving commercial success in precision fermentation requires the adoption of a cutting-edge digital approach. This approach should encompass holistic process analysis of all available data sources and the formulation of robust control strategies that are captured and deployed in digital twins. Learn how to unlock the full potential of your business with our SaaS solution Werum PAS-X Savvy.

Factsheet: PAS-X Savvy in a nutshell

Find the most important facts and benefits of PAS-X Savvy at a glance.

Factsheet: Werum PAS-X as a Service

Werum PAS-X as a Service offers all functionality of our proven pharma MES & intelligence products in a fully managed, cloud-based version. Benefit from state-of-the-art, future-proof technologies – and focus on your core business.

Factsheet: PAS-X Scheduler

Detailed planning of manufacturing processes to optimize your pharma production – powered by sedApta Factory Scheduler

Factsheet: Werum PAS-X Track & Trace

PAS-X Track & Trace provides line-controller-independent serialization and aggregation functionality for packaging processes to comply with anti-counterfeiting requirements for the pharmaceutical industry.

Factsheet: How to get the most out of your multi-fermenter data

Learn how Werum PAS-X Savvy helps you to evaluate Ambr® experiments as efficiently as possible, accelerating the whole biopharmaceutical process development.

Factsheet: Successfully implementing Werum PAS-X Savvy

Get familiar with our bioprocess software implementation strategies and accelerate your process data analytics.

Factsheet: Werum PAS-X Savvy for bioprocess data management

Bioprocess data analytics to accelerate your product commercialization

Factsheet: Werum PAS-X Weighing & Dispensing

PAS-X Weighing & Dispensing is a comprehensive package of software functionality, content and training services designed to improve the efficiency of your weighing operations.

Factsheet: Werum PAS-X Equipment Management

Easy administration and monitoring of cleaning procedures and statuses for all types of production-related objects

Factsheet: Werum PAS-X Electronic Batch Recording

Creation and execution of Master Batch Records to control, monitor, and document manufacturing processes

Fact Sheet: NextGen cloud- and AI-powered manufacturing with PAS-X MES 3.4

Boost efficiency and user experience with resilient lifecycle support on a cloud-ready, AI-powered platform

Case studies

Case Study: Novo Nordisk

It is a special bond that connects Novo Nordisk with Körber: Körber supports the digital ambitions of the global healthcare leader and acts as trusted MES partner, ecosystem provider, and rollout service partner.

Case Study: Leading healthcare company

One of the world’s largest healthcare companies implemented Körber’s NextGen PAS-X MES 3.3 in the Azure cloud in an R&D facility to reduce maintenance and upgrade effort.

Case Study: Bayer

The global life science company Bayer implements Körber’s Werum PAS-X MES at their Supply Center Beijing to accelerate manufacturing of vital medications through digitalized processes.

Case Study: Bota Bio

Time and cost savings in bioprocess operations through efficient data management

Case Study: Novo Nordisk

Novo Nordisk implements Körber’s NextGen PAS-X MES in Azure cloud environment for faster medicine delivery.

Case Study: Heel

The natural pharmaceutical manufacturer Heel automates packaging lines with NextGen PAS-X MES from Körber.

Case report: Lyell leverages Werum PAS-X MES as a Service for clinical phase production

The US-based cell therapy biotech Lyell Immunopharma has successfully taken Werum PAS-X MES as a Service into operation at their GMP production site in Bothell, WA to produce autologous T cell cancer therapies.

Case Study: Werum PAS-X MES digitizes manufacturing processes at Cipla

India’s pharma major Cipla introduces electronic batch recording to its regulated manufacturing site at Patalganga near Mumbai, significantly enhancing batch throughput and quality.

Case Study: Lupin implements EBR and paperless processes with Werum PAS-X MES

India’s pharma major Lupin benefits from Werum PAS-X MES to digitize and automate manufacturing processes at its newest injectables and oral solid dosage manufacturing site in Nagpur.

Case Study: IDT Biologika

CDMO IDT Biologika drives digitization with Werum PAS-X MES from Körber

Case Study SteriPack: Taking review-by-exception to the next level

The leading contract manufacturer SteriPack benefits from fast-track implementation and auto-batch release.

Case Study SteriPack: Taking review-by-exception to the next level (Italian)

The leading contract manufacturer SteriPack benefits from fast-track implementation and auto-batch release.

Customer Voice Sharp Packaging: Werum PAS-X MES allows for 70% reduction in batch record review time

Interview with Sharp Packaging on the benefits digitization offers its customers by implementing PAS-X MES in their Heerenveen, Netherlands packaging plant.

Customer Voice Sharp Packaging: Werum PAS-X MES allows for 70% reduction in batch record review time (Italian)

Interview with Sharp Packaging on the benefits digitization offers its customers by implementing PAS-X MES in their Heerenveen, Netherlands packaging plant.

Customer Voice AstraZeneca: How Werum PAS-X MES kept AstraZeneca's manufacturing operations running during COVID-19

Interview with AstraZeneca on the benefits of digitized processes for business resilience.

Case Study: A global pharma major implements Werum PAS-X KPI to support Lean Six Sigma

Deployment of Werum PAS-X KPI across packaging and bulk areas enables visibility of production processes and major OEE improvements.

Case Study AstraZeneca: AstraZeneca digitizes manufacturing processes with Werum PAS-X MES

Deployment of AstraZeneca's standard MES on the basis of PAS-X MES enables standardized business processes and enhanced data integrity.

Case Study Unigen: Unigen implements Werum PAS-X MES in only four months

The Japanese biotech company Unigen successfully took PAS-X MES into operation within a record time of only four months after completing the Fit phase.

Case Study: Root cause analysis in continued process verification with Werum PAS-X Savvy

A global pharmaceutical and biopharmaceutical leader relies on automated data collection and harmonization for multidimensional analysis of multiple batches across unit operations.

Case study: New England Biolabs streamlines process validation & verification

Consolidated data processing platform / Greatly reduced effort for data collection from different sources / Process intelligence supports efficient process development and faultless production runs

Case study: Accelerated PAS-X deployment during the pandemic

Dexa Medica, Indonesia’s leading pharma company, implemented Werum PAS-X MES out of the box in just ten months and largely remotely.

Case Study: Amherst Laboratories

Unilab, the leading pharma company in the Philippines, selected Amherst Laboratories – their largest toll manufacturer –for the integration of Werum PAS-X MES into their production facilities to drive operational excellence.

Case Study: Boehringer Ingelheim

At its Biberach, Germany site, Boehringer Ingelheim has built Europe’s largest biotechnology center. Whether in non-GMP labscale or in GMP-compliant settings for clinical phases I and II, process development is facilitated by Werum PAS-X MES.

Case Study: Gedeon Richter

Gedeon Richter, a major pharmaceutical company in Central Eastern Europe, has successfully implemented Werum PAS-X MES at its manufacturing plant in Grodzisk Mazowiecki, Poland, to enhance data analysis and process improvement.

Datasheets

Datasheet: BE3/BE5

Powerful & Intuitive: High speed blistering for parenteral products and medical devices

Brochure

Brochure: Modular blister future

A holistic service concept, modern and trend-setting to unlock your potential whenever you need it

Brochure: Reduce your downtime and improve your production quality.

More details on how Körber Xpert View supports you can be found in this brochure.

Flyer

Factsheet: Dividella NeoTOP Tool T1

Effortless entry into the Monomaterial Toploading Packaging style

Factsheet: Dividella NeoTOP Tool T9

Effortless entry into the Monomaterial Toploading Packaging style

Case Studies

Case Study: Winged packaging design results in cost savings

Single unit dose nasal sprayer carton for flu vaccine provides a more compact and lower cost alternative to blister packaging

Case Study: Sanofi Pasteur’s 10 count syringe carton for flu vaccine – the perfect packaging solution

The benefits of the perfect package design, in combination with our innovative machines

Case Study: Small lots at Sharp

Small lots: How Sharp meets their challenge with Dividella NeoTOP

Certificates

Safepack

For the safe and loss-free transport of parenteral medication, nothing can shake the contents of our Safepack.

Plastic Replacement

When it comes to sustainability, we are pioneers with our pharmaceutical packaging specialists.

Sustainability Report 2020

Sustainable Pharma Packaging At four locations in Allschwil (Switzerland), Ejpovice (Czech Republic), Camden (New Jersey/USA) and San Juan (Puerto Rico), up to two billion folding cartons and package inserts for the pharmaceutical and biotech industries are produced annually by over 650 employees.

Folding boxes with packaging leaflet

Packaging leaflets contain important information for patients.

Sustainable packaging solutions

From packaging design to material selection – solutions to reduce your carbon footprint

Customized packaging development

Learn more about individual, sustainable and cost-effective pharma packaging solutions

How to handle Copasafe packages

Our recommendations for ideal packaging storage conditions

Download PDF file (100 KB)

Case Study: Queisser-Pharma

More cost-effective and sustainable at the same quality: Queisser uses packaging with cold foil from Körber

Download PDF file (894 KB)

Certificates

Certificate for best Practice for Pharmaceutical Secondary Packaging compliant ECMA members Switzerland

Download PDF file (270 KB)

Certificate for best Practice for Pharmaceutical Secondary Packaging compliant ECMA members Czech Republic

Download PDF file (270 KB)

Development and production of printed and unprinted cardboard packaging. Trade in package inserts.

ISO 15378:2017

Primary Packaging Materials for Medicinal Products

Particular requirements for the application of ISO 9001:2015, with reference to Good Manufacturing Practice (GMP)

Download PDF file (139 KB)

General solutions for printed and unprinted cardboard packaging

PEFC COC / PEFC ST 2002:2020 Chain of Custody of Forest and Tree Based Products – Requirements

PEFC ST 2001:2022 PEFC Trademarks Rules – Requirements

Development and production of printed and unprinted cardboard packaging. Trade with leaflets.

ISO 9001:2015 Quality Management System

ISO 14001:2015 Environmental Management System

Download PDF file (501 KB)

Management System

Further sites according to appendix SQS

ISO 9001:2015 Quality Management System

ISO 14001:2015 Environmental Management System

Download PDF file (424 KB)

General solutions for printed and unprinted cardboard packaging

FSC COC Forest Stewardship Council – Chain of Custody

Standard reference: FSC-STD-40-003 / FSC-STD-40-004

Wilhelm Bähren GmbH & Co KG (Certificate ISO 9001)

requirements of ISO 9001:2015

Download PDF file (191 KB)

Wilhelm Bähren GmbH & Co KG (Certificate ISO 14001)

requirements of ISO 14001:2015

Download PDF file (185 KB)

Wilhelm Bähren GmbH & Co KG (Forest Stewardship Council®)

FSC Standard: FSC-STD-40-004

Download PDF file (257 KB)