How do you balance the need for innovation with the stringent regulatory requirements in the pharmaceutical industry?

Kortney: The pharmaceutical manufacturing industry has been slow to adopt cloud-based technologies due to regulatory constraints. Our white paper urges regulators to rethink these processes to enable the industry to benefit from cloud-native solutions.

Ciera: Yes, that’s true. The pharmaceutical industry is unable to fully leverage cloud-native technology due to regulatory constraints, particularly around automated updates. Every update must go through a stringent QA process, with each change carefully checked and validated.

The current level of regulation, while necessary, puts us behind other industries in terms of technological advancements. The white paper is a call to action for regulators to rethink these processes, proposing a compromise or an alternative approach to validation that would enable the pharmaceutical sector to benefit from cloud-native solutions.

Could other industries like pharma benefit from the work you're doing, or is it specific to biomanufacturers?

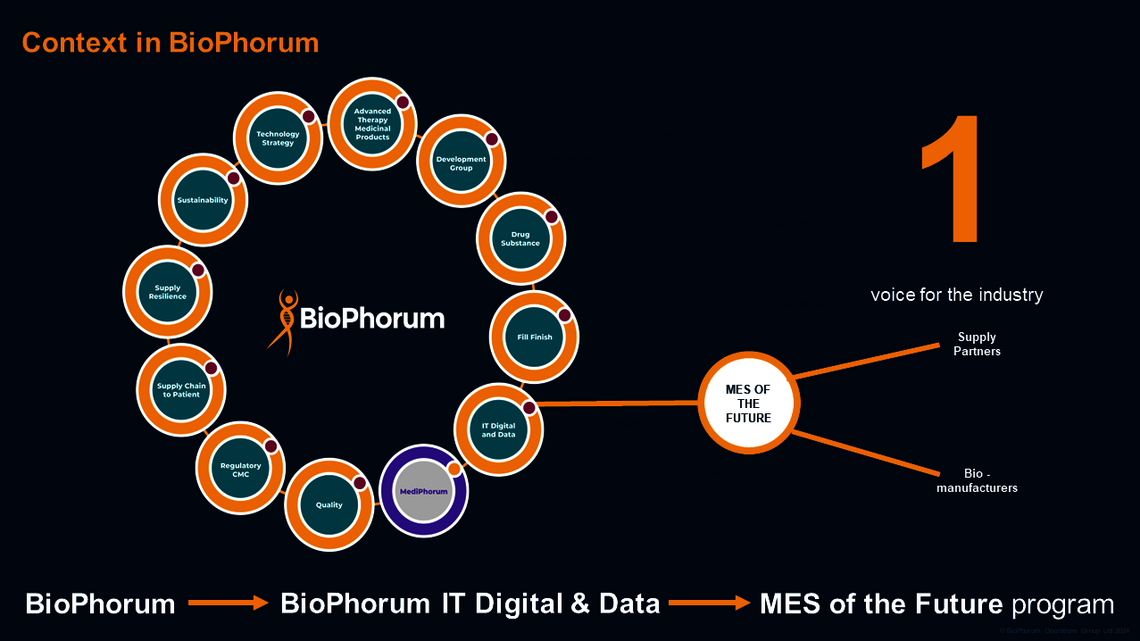

Ciera: The information we share is relevant to the broader pharmaceutical environment, including contract manufacturing organizations. Although we are called BioPhorum and have traditionally catered to the biopharmaceutical market, our scope extends to areas like IT, digital, and data.

In the future, what do you see as the most critical next steps for biomanufacturers and vendors to address collaboratively?

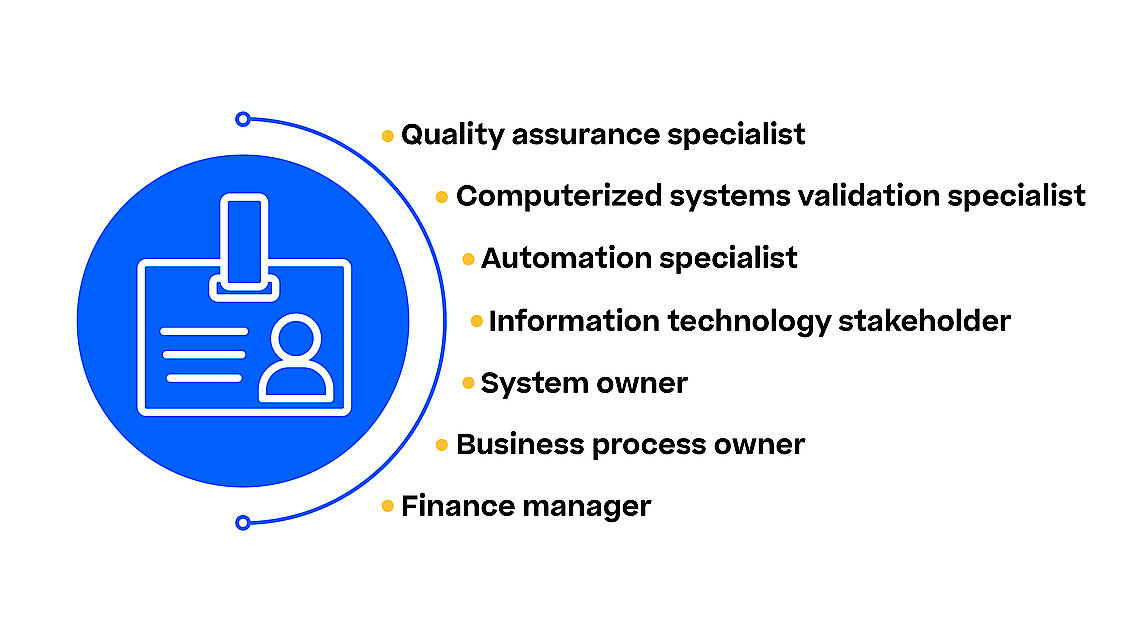

Ciera: Collaboration is key. We need to contextualize the problems and reasons for our drivers to the supply partners more accurately and with global consensus. We also need to address the operational processes associated with MES and ensure organizations are ready for digital maturity and workforce enablement. By sharing knowledge and engaging with MES supply partners, we can build a clear path towards the MES of the Future.

Kortney: I think it is important to have a space where biomanufacturers, vendors and other industry partners work together seamlessly. So ecosystems like BioPhorum are essential for driving innovation and ensuring the best possible outcomes for patients.