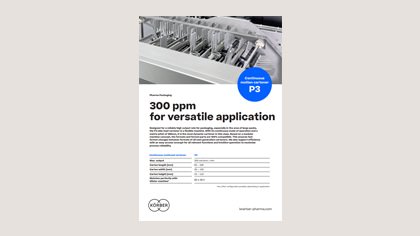

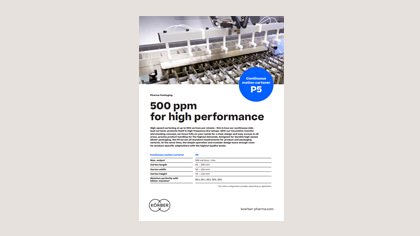

To ensure that blisters, ampoules, vials and similar reach patients safely and in compliance with GMP, packaging machines for secondary packaging must meet high requirements. The sideload cartoners from Körber are perfectly adapted to this. The flexible, modular machines allow effortless expansion of a blister, sachet or stick pack systems into a complete, high-performance production line.