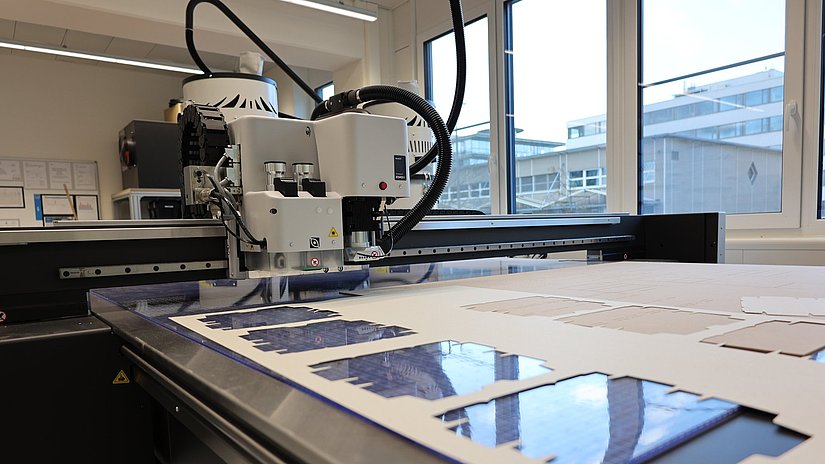

In recent years, Körber AG’s Pharma Packaging Materials Business Area has continued to broaden its expertise in the area of packaging development at its locations in Europe and the USA. Since mid-2021, Körber packaging specialists have been offering their pharma customers, at the locations in Allschwil in Switzerland, in Ejpovice in the Czech Republic and in Camden, NJ, USA, the opportunity to develop their secondary packaging in accordance with uniform standards in ‘Packaging Innovation Centers’. One particular offering is Packaging Qualification Services.0

„With our Packaging Qualification Services, we can give our customers the opportunity to quickly and flexibly test a wide range of properties and behaviors of their folding boxes and to draw valuable conclusions for the optimization of their packaging,“ explains Patric Buck, Head of Innovation Packaging Materials in Körber‘s Pharma Business Area. „This saves them the sometimes very time-consuming search for available external testing laboratories.“ Körber offers this service regardless of whether the folding boxes have been developed in-house or by another provider.