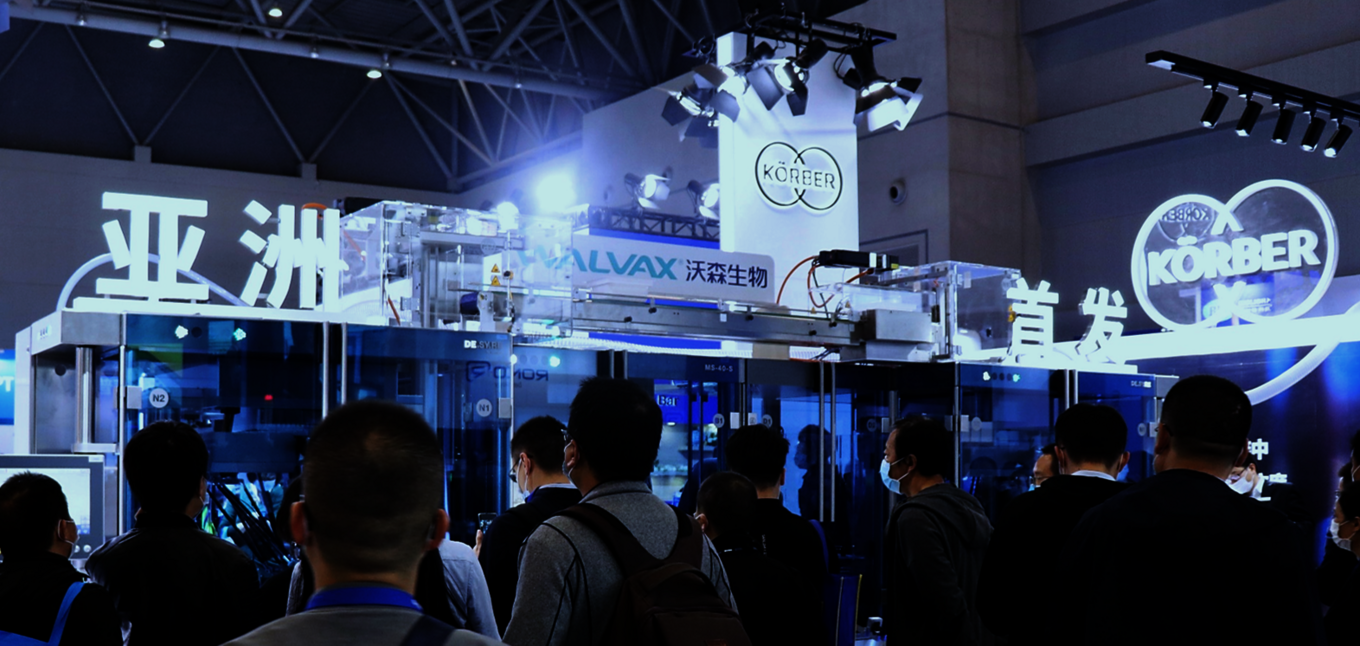

China's leading vaccine manufacturer Walvax relies on Körber inspection machine "DE.SY.RE”

The second machine at the Körber booth, a Seidenader DE.SY.RE inspection machine, will be put into operation after the show at a site of China's leading vaccine manufacturer Walvax. Junxin Huang, Director Intelligence Manufacturing and Implementation Management, reported enthusiastically about his new acquisition during the opening speech of the Körber booth at the CIPM: "We are very happy about the purchase of the inspection machine! The DE.SY.RE will be used for the production of our latest vaccines in the international production center."

The high-performance inspection system DE.SY.RE inspects syringes, cartridges and vials of different sizes for defects and contamination quickly, precisely and without contact. Up to 36,000 containers per hour are individually fed to the inspection module in the de-nester by a Delta robot, inspected and then re-nested safely and completely in a nest. Customers like Walvax can rely on the gentle, contactless handling of the products to prevent scratches and glass breakage, avoid the formation of air bubbles in the liquid and thus reduce the system's reject rate. To ensure reliable comparability and reproducibility of inspection results, each container is inspected independently of speed by each camera within the inspection module. All components of the inspection system can be adapted to customer requirements: from individual rotation profiles for each product to up to 24 images per high-resolution camera, automatic re-inspection for defined defects or, if desired, a leak test with high voltage.