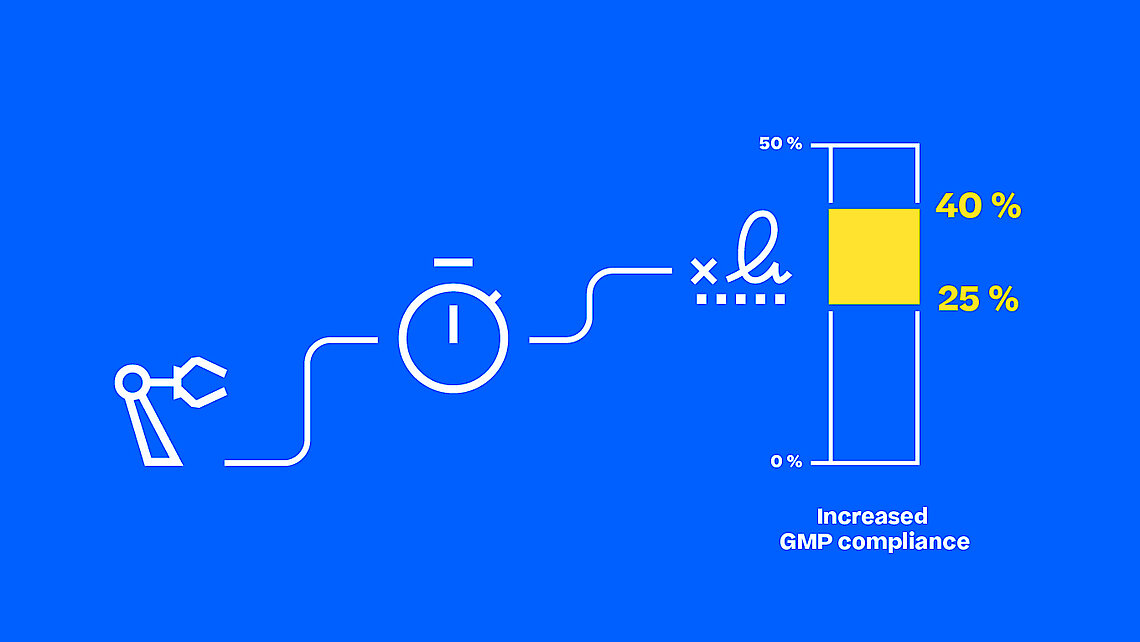

Augmented reality (AR) provides immediate access to in-depth expertise on advanced technical concepts. Time spent on training and education can be reduced by up to 25 percent while simultaneously preventing mistakes. This further step towards digitalization will make pharmaceutical companies more competitive and, above all, future-proof.

In this article:

- Using Augmented Reality to enhance the efficiency of your pharma training

- Proof of concept at a renowned pharmaceutical manufacturer

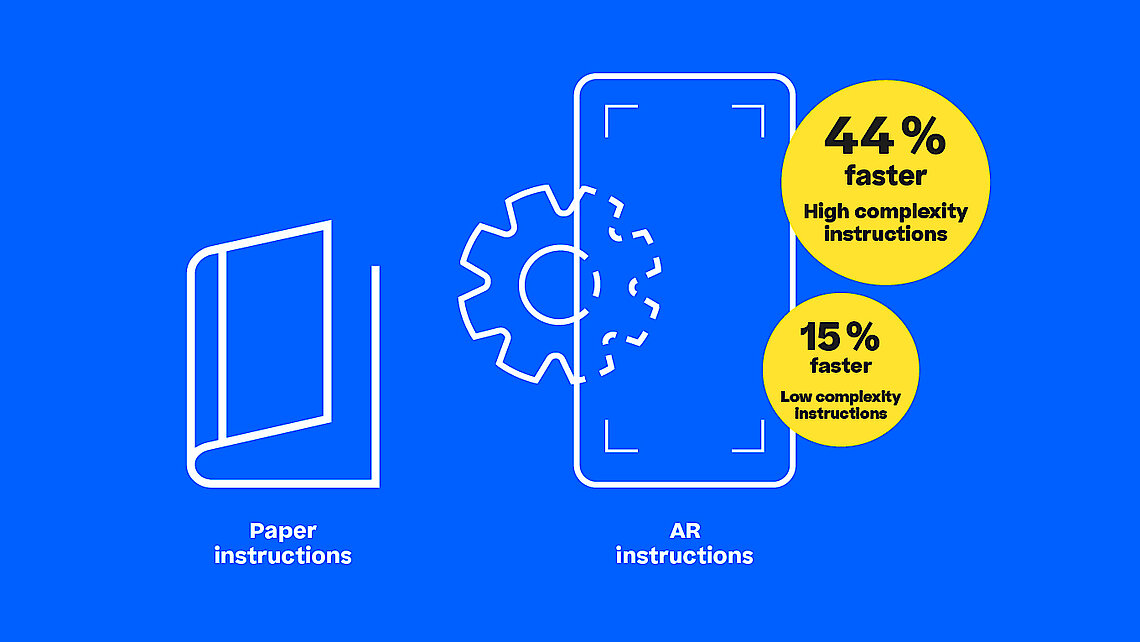

- Faster onboarding, fewer errors: the results of the proof of concept