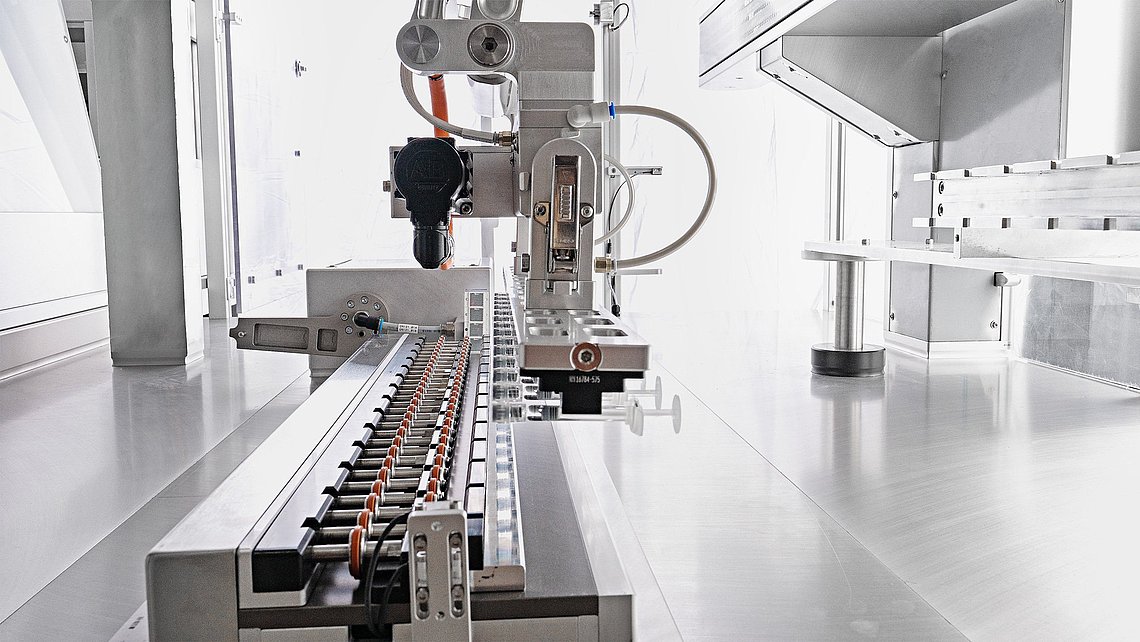

Protect your pharmaceutical products from any potential damage during their line transit. Integrate nests or trays into your line transport processes with our flexible, customizable options.

Choose from a variety of solutions for nest or tray loading and unloading. You can have them set up to work systematically with your upstream and downstream equipment, for a smooth and seamless production line for your syringes.